201/202/304/316 Stainless Steel Plate

Product Description

|

Product Name

|

201/202/304/316 201/202/304/316 Stainless Steel Plate |

|

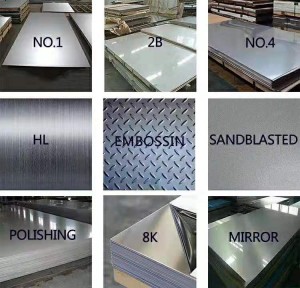

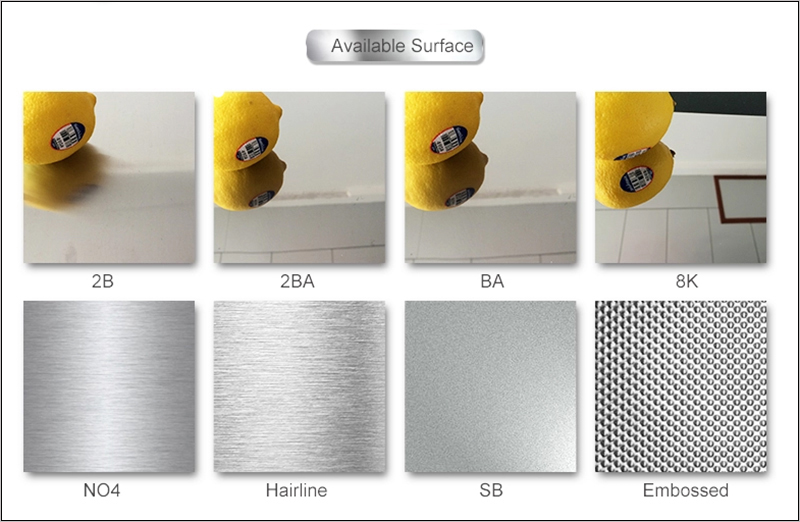

Surface Finish

|

2B / BA / HL / 8K / NO.1 / NO.4/Polished/Mirror

|

|

Stock Dimension

|

0.5-4mm x 1219×2438;0.5-4mm x 1500mm x6000mm;5mm-25mm x 1500x6000mm;8mm-80mm x 1500/1800/2000mm/2500x6000mm Cutting according to customeized |

|

Service

|

OEM, customized sizes. customized fabrication by drawings |

|

Cutting Type

|

laser cutting;water-jet cutting |

|

Cutting Tolerance

|

+/- 0.3mm |

|

Application

|

Costruction Industry/Kichten Products/Fabrication Industry/Home Decoration |

Chemical Composition

|

Grade

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Ni

|

Others

|

|

201

|

≤0.15

|

≤1.00

|

5.5-7.5

|

≤0.06

|

≤0.03

|

16.0-18.0

|

3.5-5.5

|

N≤0.25

|

|

202

|

≤0.15

|

≤1.00

|

7.5-10.0

|

≤0.06

|

≤0.03

|

17.0-19.0

|

4.00-6.00

|

N≤0.25

|

|

304

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.045

|

≤0.03

|

18.0-20.0

|

8.0-10.5

|

|

|

304L

|

≤0.03

|

≤1.00

|

≤2.00

|

≤0.045

|

≤0.03

|

18.0-20.0

|

8.0-10.5

|

|

|

309S

|

≤0.08

|

≤1.00

|

≤200

|

≤0.045

|

≤0.03

|

22.0-24.0

|

12.0-15.0

|

|

|

310

|

≤0.25

|

≤1.5

|

≤2.00

|

≤0.045

|

≤0.03

|

24.0-26.0

|

19.0-22.0

|

|

|

316

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.045

|

≤0.03

|

16.0-18.0

|

10.0-14.0

|

Mo:2-3

|

|

316L

|

≤0.03

|

≤1.00

|

≤2.00

|

≤0.045

|

≤0.03

|

16.0-18.0

|

10.0-14.0

|

Mo:2-3

|

|

321

|

≤0.08

|

≤1.00

|

≤2.00

|

≤0.045

|

≤0.03

|

17.0-19.0

|

9.0-13.0

|

Ti≥5*C%

|

|

409

|

≤0.08

|

≤1.00

|

≤1.00

|

≤0.045

|

≤0.03

|

10.5-11.75

|

≤0.5

|

Ti:6C-0.75

|

|

409L

|

≤0.03

|

≤1.00

|

≤1.00

|

≤0.04

|

≤0.03

|

10.5-17.5

|

Ti:6C-0.75

|

|

|

410

|

≤0.15

|

≤1.00

|

≤1.00

|

≤0.04

|

≤0.03

|

11.5-13.5

|

||

|

410L

|

≤0.03

|

≤1.00

|

≤1.00

|

≤0.04

|

≤0.03

|

11.0-13.5

|

Surface Finish

|

Surface Finish

|

Defination

|

Application

|

|

2B

|

Those finished,after cold rolling,by heat treatment,picking or other equivialent treatment and lastly by cold rolling to given appropriate luster

|

Medical equipment,Food industry,Construction material,Kitchen utensils

|

|

BA

|

Those processed with bright heat treatment after cold rolling

|

Kitchen utensils,Electric equipment,Building construction

|

|

No.1

|

The surface finished by heat treatment and picking or processes corresponding tjere to after hot rolling

|

Chemical tank,pipe

|

|

No.4

|

Those finished by polishing with No.150 to No.180 abrasives specified in JIS R 6001

|

Kitchen utensils,Building construction,Medical equipment

|

|

HL

|

Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size

|

Building construction

|

|

8K

|

A mirror-like reflective surface by polishing with finer abrasives over 800 mesh

|

Reflector,Mirror,Interior-Exterior decoratio

|